Description

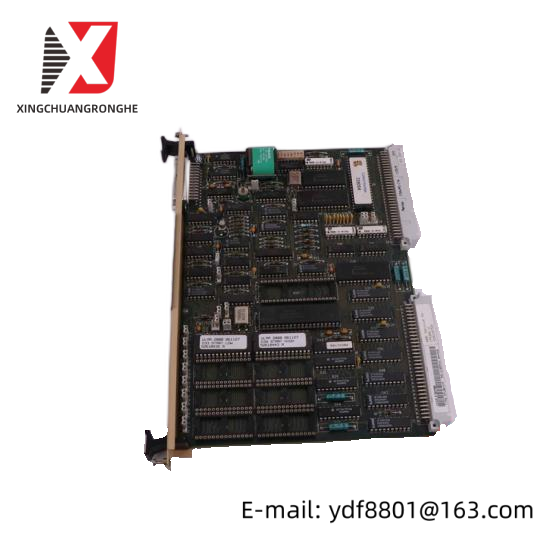

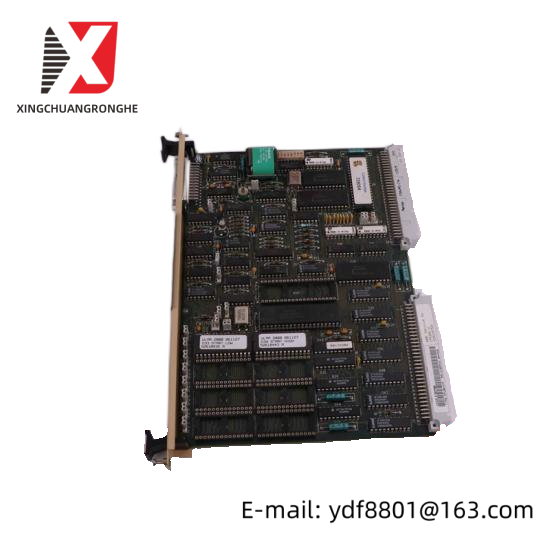

ABB A06B-6124-H209

1. Brand:ABB

2. Model:A06B-6124-H209

3. Type:Encoder Module

4. Application Range:High-precision motion control systems

5. Operating Temperature:-20°C to +70°C

6. Power Consumption:≤ 1.5W

7. Connectivity:RS-485 interface

8. Rotation Sensitivity:0.001°

9. Mechanical Compatibility:Suitable for various industrial robots and automation systems

The A06B-6124-H209 encoder module is engineered for seamless integration into advanced industrial automation setups, providing unparalleled accuracy and robustness.

With a wide voltage range of 12V to 48V DC, this encoder ensures compatibility across diverse industrial environments, guaranteeing reliability under varying power conditions.

Featuring support for multiple communication protocols, including RS-422, CANopen, and EtherCAT, the A06B-6124-H209 facilitates smooth data exchange with other devices in the system, enhancing overall operational efficiency.

Engineered for durability and precision, the module withstands harsh operating temperatures from -25°C to +85°C, ensuring continuous performance in extreme conditions.

Its compact design, measuring 105mm x 48mm x 46mm, makes it an ideal choice for space-constrained applications without compromising on functionality or performance.

ABB Main Series

| ABB Accuray | ABB H&B Contrans T | ABB RAZOA | ABB Procontrol P13 |

| ABB Advant OCS | ABB H&B Contronic | ABB Robots | ABB Procontrol P14 |

| ABB Advant-800xA | ABB H&B Freelance 2000 | ABB SattControl | ABB Fischer & Porter DCI |

| ABB Bailey Infi 90 and Net 90 | ABB Master | ABB Synpol D | ABB UNITROL |

| ABB Commander | ABB MOD 300 | ABB Taylor MOD 30 | ABB Procontic |

| ABB Drives | ABB MOD 30ML/MODCELL | ABB Triguard | ABB Turbotrol |

| ABB Electrical |

Our purpose

A Distributed Control System (DCS) is a computer-based system used to automate, monitor and control complex industrial processes. It is typically used in large plants such as refineries, power plants, chemical plants, and paper mills.

A DCS consists of several components that work together to control the process. These components include:

1. Controllers:These are devices that receive input from sensors and send output signals to actuators. Controllers use pre-programmed logic to control the process.

2. Sensors:These are devices that measure physical quantities such as temperature, pressure, flow, and level.

3. Actuators:These are devices that control physical processes such as opening and closing valves, starting and stopping motors, and adjusting dampers.

4. Operator stations:These are human-machine interfaces (HMI) that allow operators to monitor the process, make changes to setpoints, and troubleshoot problems.

5. Communication network:This network connects all of the components of the DCS together.

Reviews

There are no reviews yet.