Description

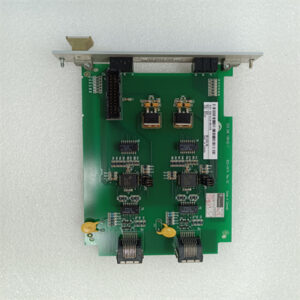

The GE DS200ADGIG1AAA is a printed circuit board (PCB) that is part of General Electric’s Mark V Speedtronic system. The board is used to control the speed and torque of a turbine.

The PCB is approximately 8 inches by 6 inches in size. It is made of a fiberglass substrate with copper traces and components. The board has a carrier board and a secondary daughterboard. The carrier board is the main board and contains the majority of the components. The daughterboard is a smaller board that is attached to the carrier board. It contains additional components that are not needed for all applications.

The board is populated with a variety of components, including integrated circuits (ICs), resistors, capacitors, and connectors. The ICs are the main logic components of the board. They control the operation of the turbine. The resistors and capacitors provide electrical resistance and capacitance, respectively. They are used to filter signals and provide power to the ICs. The connectors are used to connect the board to other components of the system.

Factory automation solutions can provide the following advantages for other industrial automation companies around the world:

Enhancing competitiveness: Factory automation can help businesses improve productivity, quality, efficiency, and safety, thereby enhancing competitiveness.

Expanding market share: Factory automation can help businesses enter new markets and meet the needs of new customers, thereby expanding market share.

Creating new sources of revenue: Factory automation can help businesses provide new services and solutions, thereby creating new sources of revenue.

In summary, factory automation solutions can provide a wide range of advantages for the oil and gas industry, EPC contractors and system integrators, as well as other industrial automation companies around the world. These advantages can help businesses improve productivity, quality, efficiency, safety, competitiveness, and profitability.

Reviews

There are no reviews yet.