Description

Technical Parameter

Connector Type:USB

Port Compatibility:USB 2.0

Connection Protocol:RS-232

Data Transfer Rate:Up to 115,200 bps

Software Compatibility:Proficy Machine Edition, FactoryTalk View

Operating Temperature:-22°F to 140°F (-30°C to 60°C)

Operating Humidity:5% to 95% non-condensing

Dimensions:Approx. 5.5 x 2.2 x 0.7 inches

Weight:Approx. 0.2 lbs.

Product Details

Introducing the GE FANUC IC690USB901 PLC Programming Cable – your essential tool for managing industrial automation systems. This robust cable ensures stable data transfer and easy connectivity, making it indispensable for system engineers and maintenance personnel alike.

Engineered with high-quality materials, the cable boasts a durable design capable of withstanding harsh industrial environments. Its compact yet sturdy construction guarantees reliable performance over extended periods, ensuring minimal downtime and maximizing productivity.

With compatibility specifically tailored for GE Fanuc IC690 series PLCs, this programming cable simplifies the integration process, allowing for quick and efficient setup. It supports high-speed USB 2.0 data transfer, enabling rapid exchange of information between your PLC and computer without compromising on performance.

Designed for comfort and convenience, the IC690USB901 comes with an intuitive user interface that facilitates easy navigation through various functions. Whether you’re performing routine diagnostics or complex programming tasks, this cable streamlines your workflow, saving valuable time and effort.

For those requiring flexibility, the cable is available in standard lengths with the option to customize to specific needs. This ensures that it can accommodate a wide range of applications, enhancing its adaptability across different industrial settings.

What is DCS ?

A Distributed Control System (DCS) is a computer-based system used to automate, monitor and control complex industrial processes. It is typically used in large plants such as refineries, power plants, chemical plants, and paper mills.

A DCS consists of several components that work together to control the process. These components include:

1. Controllers:These are devices that receive input from sensors and send output signals to actuators. Controllers use pre-programmed logic to control the process.

2. Sensors:These are devices that measure physical quantities such as temperature, pressure, flow, and level.

3. Actuators:These are devices that control physical processes such as opening and closing valves, starting and stopping motors, and adjusting dampers.

4. Operator stations:These are human-machine interfaces (HMI) that allow operators to monitor the process, make changes to setpoints, and troubleshoot problems.

5. Communication network:This network connects all of the components of the DCS together.

***********************************************************

Annual hot selling advantage products:

ABB PM891

First hand source, affordable price. Spot inventory!

•Shipping Port: Xiamen

•Ship to you via Fedex/DHL/TNT/UPS/EMS

•Package: Original packing with cartons

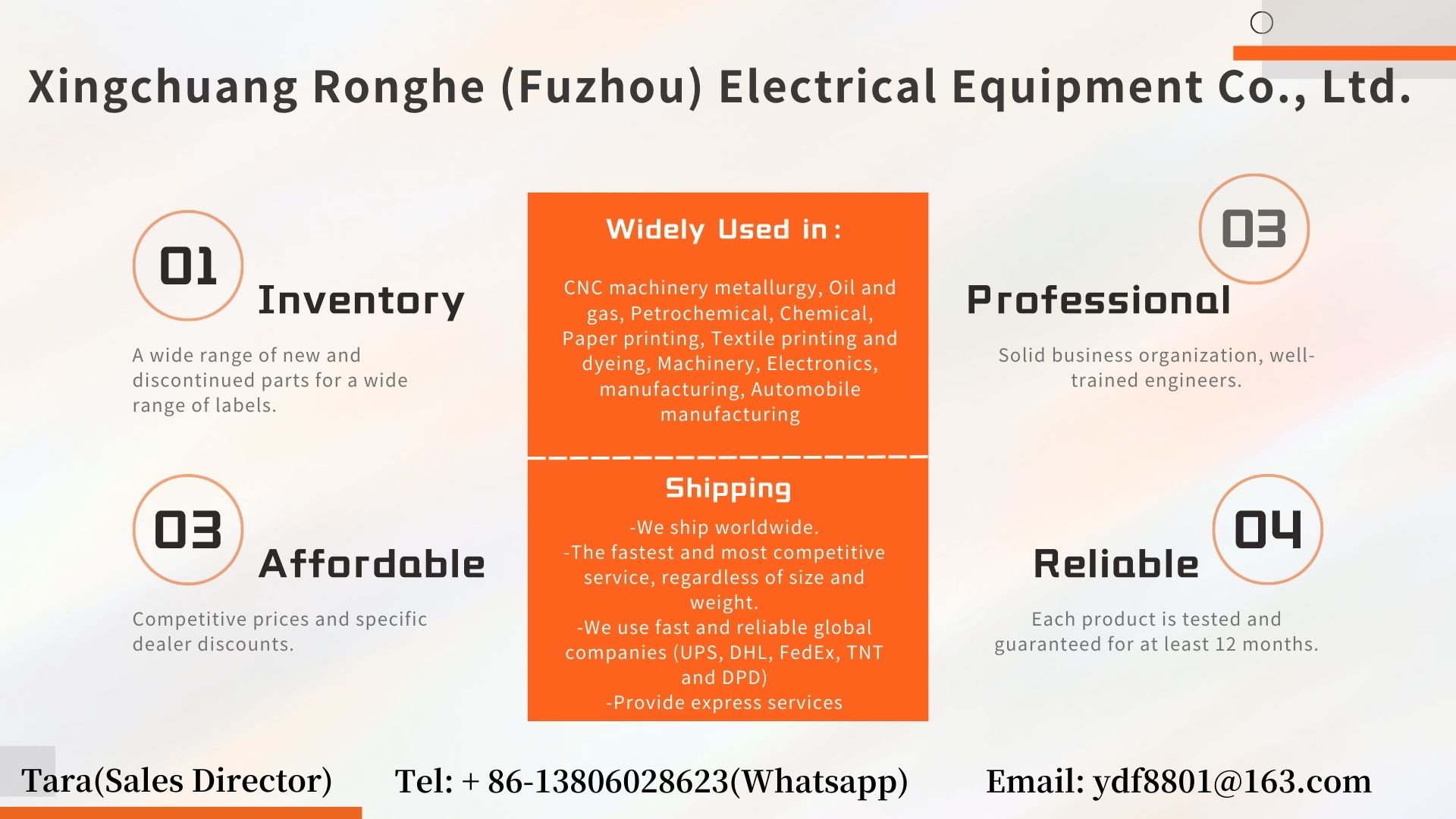

About Us

Xingchuang Ronghe (Fuzhou) Electrical Equipment Co., Ltd. is a professional company specializing in international trade. We have rich industry experience and extensive customer resources, and can provide personalized trade solutions for customers.

Our advantages are mainly reflected in the following aspects:

1. Product diversification: We represent a wide range of products that can meet the needs of different customers.

2. Service specialization: We have a professional team that can provide customers with comprehensive services.

3. Diversified channels: We have established long-term and stable cooperative relationships with multiple domestic and foreign enterprises, and can provide customers with various trade channels.

4. Price advantage: By optimizing the supply chain and reducing costs, we are able to provide customers with competitive prices.

Reviews

There are no reviews yet.